NEWS RELEASES

Products and Technology

Mazda Develops new Clean Diesel Engine with Improved Output and Environmental Performance

- Engine features new DPF with independently-developed, world-first catalyst activation mechanism -

|

HIROSHIMA, Japan—Mazda Motor Corporation has developed a greatly improved clean diesel engine that offers output and environmental performance comparable to a gasoline engine. It will be progressively introduced to markets around the world, beginning in Europe in 2009.

The newly developed MZR-CD 2.2 clean diesel engine has a displacement ten percent greater than Mazda’s current MZR-CD 2.0-liter diesel, and achieves top class torque of 400 Newton meters. Improved fuel injectors and a lower compression ratio contribute to its enhanced fuel efficiency. Additionally, the engine’s diesel particulate filter (DPF) features a Mazda-developed world-first catalyst activation mechanism that enhances the removal of particulate matter (soot) from the exhaust gases. The new catalytic combustion treatment process enables the DPF to burn off particulate matter approximately 60 percent faster than current systems. Due to this technical advancement, the MZR-CD 2.2 is clean enough to qualify for the Euro 5 emissions standards. (This is based on a Mazda in-house assessment.)

Furthermore, the addition of a dual balance shaft and a more rigid engine block has resulted in a significant reduction in engine vibration, and helps achieve extremely quiet operation.

Main features of the new MZR-CD 2.2 clean diesel engine

Newly developed diesel particulate filter (DPF) Mazda’s new clean diesel engine has a high thermal resistance diesel particulate filter (DPF) with a catalyst that optimizes the combustion of soot in the exhaust. The catalyst features a proprietary world-first activation mechanism. Combined with more precise engine control, this mechanism doubles the interval between DPF regeneration cycles, and reduces the time to complete the regeneration process to a third of the time necessary for conventional systems.

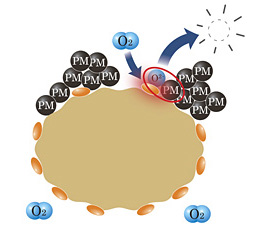

Catalysts use the oxygen contained in exhaust gases to burn off particulate matter. In order to initiate combustion, the temperature of the exhaust gas must be increased. This requires additional fuel, which adversely affects overall fuel economy.

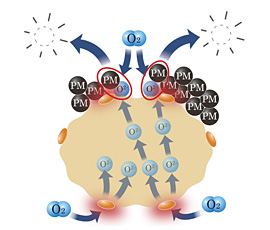

The ceramic base material in Mazda’s unique catalyst has a molecular structure that enables the easy movement of oxygen stored within it. This extra oxygen can be supplied as required to significantly increase the rate of particulate matter combustion, effectively the DPF regeneration speed.

As a result, the new catalyst mechanism reduces the amount of fuel required to burn off the particulates (soot). This improves the overall fuel economy, and results in lower CO2 emissions and cleaner exhaust gases.

Diagrams showing ceramic base materials

|