NEWS RELEASES

Products and Technology

Mazda Develops World’s First Steel and Aluminum Joining Technology Using Friction Heat

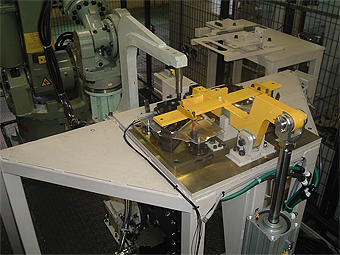

HIROSHIMA--Mazda Motor Corporation has developed the world’s first direct spot joining technology to join steel and aluminum. This new technology was first employed in 2003 in the development of the Mazda RX-8 sports car that used friction heat to join separate aluminum sheets. The technology has evolved, and will be used to join the trunk lid and bolt retainer for the updated and improved Mazda MX-5 sports car that is scheduled to go on sale around the world in the latter half of 2005. Up to now, welding two different metals such as steel and aluminum has been a difficult task. However, by optimizing the rotating tool shape and joining characteristics, and by using galvanized steel on one side, joining steel and aluminum has been made possible. The process is similar to that of joining two pieces of aluminum, when a joining gun holds the parts from both sides with a welding tool. The joining tool is then made to spin while force is applied, which in turn generates frictional heat that subsequently joins the aluminum materials to the steel sheet metal. Galvanized steel helps prevent the galvanic corrosion that results from the contact of two different types of metal. Compared with conventional joining techniques such as riveting or clinching, steel and aluminum spot friction welding makes it easier to join materials that are difficult to deform, such as aluminum casting and high tensile steel. Additionally, running costs can be reduced because riveting becomes unnecessary.

This innovative technology makes it simple to join steel

and aluminum, and improves the potential of coupling aluminum parts

to steel in vehicle bodies, and has other applications in a wide

range of industrial uses. The process contributed significantly to Mazda’s

vehicle weight reduction efforts during the development of the MX-5

sports car, where each gram was counted, as well as lowering costs.

Mazda has applied for over twenty patents related to this technology. |